News List

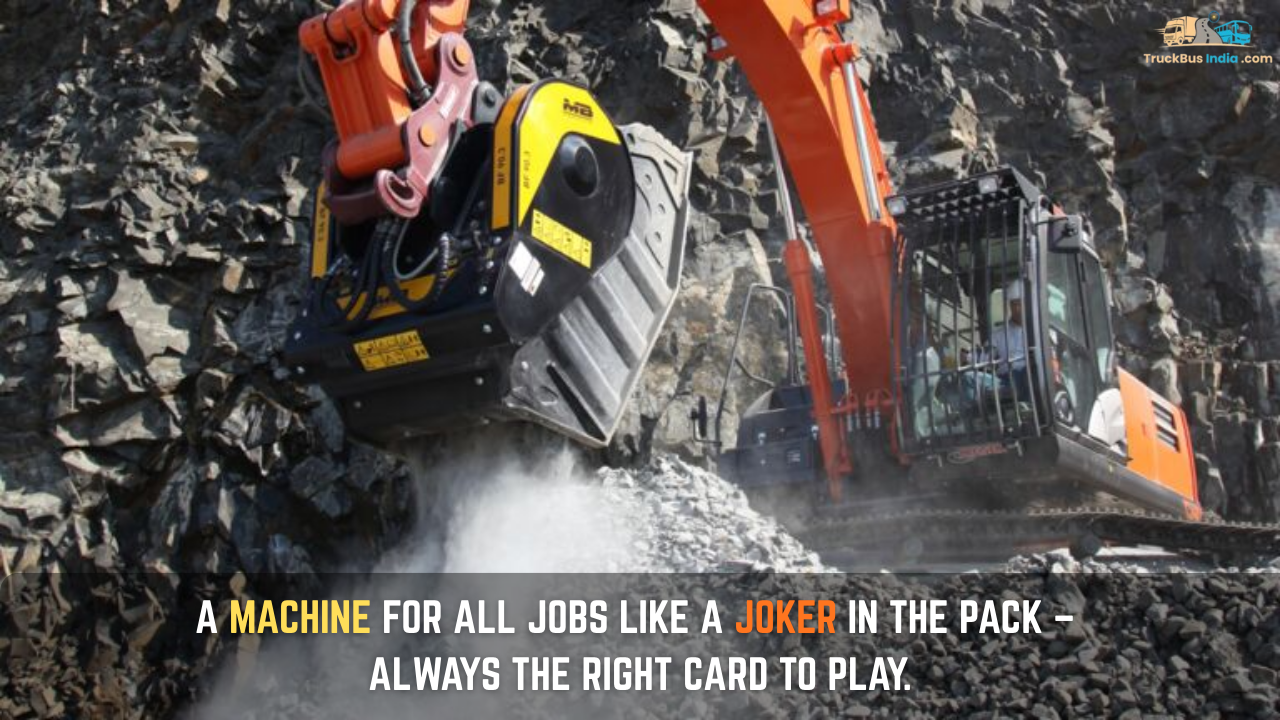

MB Crusher: One Machine, Endless Possibilities

Versatile Solution Across Diverse Sites

MB Crusher’s screening and padding buckets are redefining efficiency on construction, quarrying, and environmental sites. From Spanish kaolinite quarries to the snowy slopes of the French Alps, these machines demonstrate unmatched adaptability. Whether handling kaolin processing, trench backfilling, or delicate environmental areas, the MB Crusher line delivers high performance and sustainability. Operators can now manage multiple tasks on a single site without the need for multiple machines.

Efficiency at Spanish Kaolinite Quarries

In Spain, kaolinite, a key mineral for paper and porcelain, was traditionally crushed under excavator tracks or manually processed, a method that was inefficient and costly. The MB-HDS323 padding bucket now extracts, stores, dries, and processes the mineral on site, providing high-quality, neatly sorted material. This approach reduces waste, enhances productivity, and ensures a cleaner and safer operation.

Innovative On-Site Solutions in the Alps

High in the French Alps, MB Crusher equipment addressed a logistical challenge in snowmaking pipeline installation. Using the MB-HDS320 mounted on a CAT320, teams screened and prepared excavated material on site and reused it as backfill. The result was uniform, ready-to-use material without the need for transport, significantly reducing costs and environmental impact. Similar operations at German sites, including the environmentally sensitive island of Sylt, show the machine’s ability to process sand, peat, and soil directly on location.

Patented Shaft System Enables Rapid Adaptation

MB Crusher’s versatility comes from its patented rotor system, allowing operators to switch between materials in minutes. From soil to sand, glass to green waste, each rotor can be swapped directly on site without workshop intervention. This design has transformed projects such as ENEDIS AUVERGNE’s power line construction in France, where reusable backfill is separated from spoil with precision, saving time, money, and natural resources.

Expanded Product Range for Every Excavator

The MB-HDS line now features 13 models for various equipment sizes. The MB-HDS407 is an ultra-compact option for 3.5–9 ton excavators and backhoes, perfect for tight spaces, while the MB-HDS533 is a 3.4-meter-wide powerhouse for 50–80 ton excavators handling large-scale projects and challenging materials. Every model emphasizes adaptability, speed, and efficiency.

Driving the Future of On-Site Material Processing

MB Crusher is transforming the concept of a machine for every job into one machine for all jobs. By providing a solution that works across seasons, materials, and sites, from quarries to mountain slopes, the company is setting a new benchmark in construction and material processing. With reduced waste, enhanced productivity, and environmental awareness, MB Crusher’s padding buckets prove that true versatility begins at the operator’s fingertips.